-1.jpg?1611379381)

There's no question that 3D printing is here to stay. However, it is still a developing technology that raises certain questions: Is it really effective for massive and large-scale construction? How sustainable is it? Will it go from being an option to becoming the norm in the construction industry?

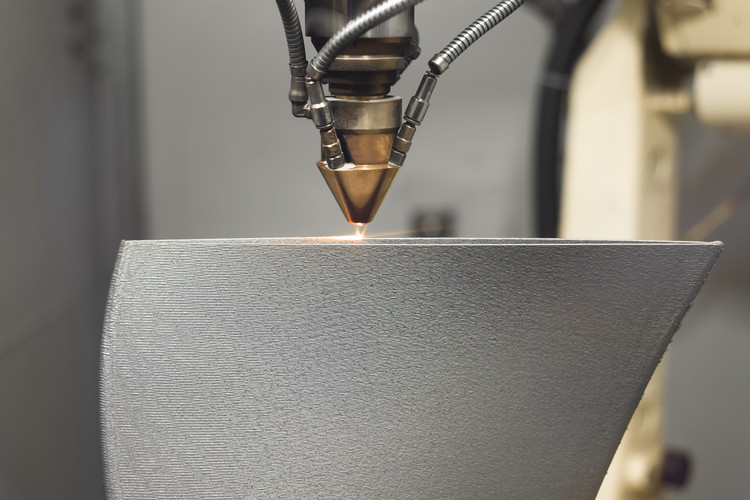

To help clarify the broader picture of 3D printing's place in architecture and construction, we spoke with Alain Guillen, Managing Director and Co-founder of XtreeE. XtreeE is a platform that allows architects to bring their designs to reality through advanced large-scale 3D printing, which generates quick and precise shapes without material waste. Read below to find out how he and his team envision the future of robotics in architecture and why architects should prepare to embrace this new technology, leading us toward a more efficient yet equally creative future.

.jpg?1582834753)

.jpg?1582834791)