Cross Laminated Timber (CLT) is a type of prefabricated timber building material that has similar strength and stability to traditional concrete and steel structures. Egoin offers CLT panels made from structural grade sawn timber finger-jointed boards, which are laid up and glued perpendicular to each other. These panels typically have an odd number of layers, though extra layers can be added to improve their span capability, fire rating, or aesthetic appeal. Egoin's CLT panels primarily use timber falling into higher C Classes—such as C22 or C24—with lower strength classes—C16, and C18—possibly used in the core in cases where structural performance is less critical.

As a leading provider of timber construction solutions, Egoin specializes in the design, engineering, and manufacturing of CLT panels. They prioritize environmental responsibility in their manufacturing processes, sourcing their CLT panels from sustainably managed local forests and using PEFC-certified wood fiber.

Applications

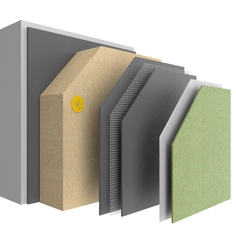

Egoin's CLT panels can be applied as walls, floor slabs, and roof elements, and be left exposed for a natural finish. CLT panels are designed, engineered, and machined for specific purposes, originating from a master panel typically 3m wide and up to 14m long. The thickness of the panels ranges from 90mm to 400mm depending on structural requirements. Egoin uses CNC machines and CAD CAM software to ensure high tolerance standards, and the kits are delivered to the site along with fixings, connections, and installation plans.

Advantages

- Swift construction

- Reduction of program and preliminary costs

- Lighter structures

- Minimization of foundation mass requirements

- Augmented building opportunities in certain locations

- Sustainable construction systems aligned with Egoin's carbon reduction targets