-

Use

Alusion™ ALFG-12.7-LM-2S - Lightweight panels, exterior facades, interior walls, ceilings, cabinets, doors, tabletops, furniture, showroom displays, lighting, fixtures, exhibits, signage, etc. -

Applications

Commercial and Residential facades, Retail stores, hotels etc. -

Characteristics

Produced as with a continuous casting production method, flat sheets, 100% recyclable, and contains approximately 20% + recycled content. -

Colors

Silver – Natural Aluminum -

Sizes

L, 1220 mm W x 2440 mm L, 1220 mm W x 3048 mm L, 1220 mm W x 3660 mm L (4’ x 8’, 4’ x 10’, 4’ x 12') Custom sized & longer panels also available upon demand | Standard thicknesses available in 12.7mm, 25.4 mm and 43.2 mm (1/2”, 1” & 1.7”)

Cymat Technologies Ltd is a world leader and has exclusive rights in the production of Stabilized Aluminum Foam (SAF). Based in Toronto, Canada, it is an innovative materials technology company that uses Alusion™ Stabilized Aluminum Foam to make lightweight aluminum panels.

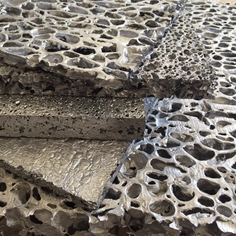

Cymat’s Stabilized Aluminum Foam, marketed under the trade name of Alusion™ for architecture, is a versatile and unique material with virtually limitless design and architectural applications. As well as its unique appearance, the aluminum foam panels have sound-absorbing properties making them ideal for applications requiring both acoustic attenuation and beauty.

The lightweight aluminum panels created by Alusion™ foam are strong yet lightweight and similar in appearance to a metallic sponge. It is visually striking, with a modern dramatic look. For architecture, the aluminum foam panels are produced in 12.7mm, 25.4mm, and 43.2mm thicknesses (1/2”, 1” & 1.7”) and three densities (Large Cell, Mid Cell & Small Cell, custom also available). Each thickness and density has its own representative stress/strain curve.

Alusion™ Stabilized Aluminum Foam (SAF) is buoyant, flame, and corrosion resistant in the same way as aluminum. The surface of the material is either left in its solid form as produced or undergoes surface preparations that provide many different appearances from a solid surface “shimmering” look to a translucent “water froth” look.

The Alusion™ product is produced with a proprietary continuous panel production process, which allows it to have many advantages. The product’s competitive edge is that no one can produce aluminum foam in the dimensions and volumes that Cymat Technologies Ltd can provide, with the overall consistency or even with the random yet uniform look in which it is created. It is lightweight and easy to install and is 100% recyclable.

- Modern and dramatic appearance.

- The Alusion™ product is 100% recyclable and contains between 20%-100% recycled content.

- Acoustic absorption properties.

- Non-combustible with a flame spread of zero.

- Highly corrosion resistant.

- The strength, durability, and resilience of aluminum.

- Windload testing available upon demand (220 mile per hour + / 354 km/hr+).

- Colors available: Luminous Silver color (aluminum) which can also be powder coated in limitless color choices.

Other Surface Solutions

The aluminum foam panels can be resin coated, laser-cut, and water jet cut with a specialized WJ process only by Cymat Technologies Ltd. Special powder coatings and wet paints can be applied which render the product 100% salt resistant and chemically resistant.

ALFG-12.7-LM-2S – LM 2 sides open is somewhat translucent, and is available in thicknesses of: 12.7mm & 25.4mm.

Standard panel size 1220mm W x 2440mm L, 1220 W x 3048 L, 1220 W x 3660 L (4’ x 8’, 4’ x 10’, 4’ x12’)

ALFG-12.7-LM Natural also available – With cells closed is also available in thicknesses of: 12.7mm & 25.4mm

Alusion™ ALFG-12.7-LM-2S - Open Cell Two Side open

Alusion™ ALFG-12.7-LM – Natural, closed-cell (available in 12.7mm & 25.4mm)

Alusion™ Open Cell One Side open Top - available in 12.7mm & 25.4mm (custom thicknesses also available)