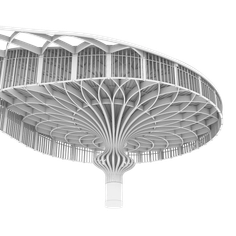

Blumer Lehmann is a material- and system-independent specialist for custom timber construction products and components. Their timber framing center uses high-end CNC processes for maximum precision, flexibility and speed. Together with a streamlined organization, Blumer Lehmann can provide efficient, competitive services. They offer 3D production planning for high-performance 5-axis timber framing and can machine beams and panels into almost all desired forms.

Minimal tolerances, maximum flexibility

The framework for producing components is based on mathematically exact, parameterized models. This is how they ensure that tolerances are kept to a minimum to guarantee a smooth construction and installation process. The development of these models is part of the process.

Blumer Lehmann's component management system displays a real-time overview of the production and the equality of every component for maximum quality and effectiveness. This allows them to provide their customers with fully customized components within budget, on schedule and highest quality.

Check out one of Blumer Lehmann's projects here: Tamedia Office Building / Shigeru Ban Architects.

If you desire more news about Blumer Lehmann register here for their newsletter.