-

Use

Roof waterproofing systems -

Applications

Hospitality -

Characteristics

Durable, single-ply membrane, lightweight, quick and easy to install, flexible, sustainable -

Certification

Approved by KOMO, ATG, DTA, ETN, DiT, abP, FLL -

Guarantee

10 years

Elevate has 40 years of experience in roofing solutions that ensure performance and protect communities. Elevate's Roofing Membrane - RubberGard EPDM was chosen to waterproof The Lodges at Feldon Valley Hotel in the Cotswolds, in the south of England.

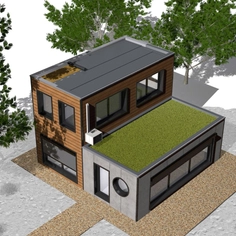

Designed by Design Engine Architects to complement their natural setting, the smaller lodges are connected to the main building via a raised boardwalk and provide a secluded, natural, and relaxing getaway destination with views of woodland and rolling countryside. The project’s lead architect, Amanda Moore, explains: "The client was very clear that the vision for the project was to create a hotel that complements the natural setting and makes use of natural materials, so the satellite lodges have been designed as a homogenous shape with natural timber cladding. We needed a waterproofing membrane that could encapsulate the battening system for the timber cladding on the pitched roof and Elevate’s RubberGard EPDM roofing system provided the ideal solution as it enabled much faster and simpler detailing to seal each batten and work with the pitch of the roof. Indeed, we have been so impressed with the system that we have since invited the company to deliver a CPD presentation to our design team."

|

Elevate Authorised Contractor Weatherfix FRS was appointed to carry out the installation of the RubberGard EPDM roofing membrane on each of the four satellite lodges. The membrane was installed onto the roof of all four small lodges within just four days, enabling the main contractor to begin work on the interiors. The battens were then installed onto the completed roofing membrane and Weatherfix FRS began the process of carrying out the detailing for the 400+ battens on the roofs. Once the waterproofing had been completed, the timber cladding was installed on the roof and external walls.

Oliver Sweeney from Weatherfix FRS comments: "The level of detailing required to incorporate more than 400 battens into the waterproof roof surface meant that it would have been cost-prohibitive to use felt-based systems because installation would have been so labor-intensive. Conversely, the water-based adhesive, tapes and ease of detailing offered by the RubberGard EPDM system made the detailing much faster and easier to achieve."

Project Details

| Location | Cotswolds, England |

| Year | 2019 |

| Architect | Design Engine Architects |

| Contractor | Weatherfix FRS |

| Type of Building | Hospitality |

| Product Used | RubberGard EPDM |