-

Use

Metal roofing and walls -

Applications

Residential, commercial, agricultural -

Characteristics

Durable, versatile, easy application

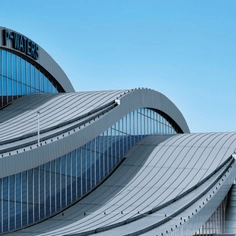

Metal wall systems are known for their versatility in both aesthetics and performance, making them suitable for a variety of commercial projects, ranging from dairy barns to educational buildings to stadiums. These wall panels are typically available in steel and aluminum and are suitable for use in various climates. Understanding how to determine the best solution for each project, is a key aspect to potentialize Fabral's ample offering of creative design solutions.

Characteristics of Metal Wall Panels

Metal wall panels provide several practical advantages that should be taken into account when choosing the right system.

- Color Options: Manufacturers typically offer a broad spectrum of colors, ranging from neutral tones to vibrant shades.

- Durability: These panels are designed for longevity, with lifespans often exceeding 50 years, depending on the material and manufacturer.

- Sustainability: Many metal panels are composed of 35% to 85% recycled materials and are fully recyclable.

- Weight: Metal panels are relatively lightweight, with aluminum weighing between 0.4 to 0.8 pounds per square foot and steel between 1 to 2 pounds per square foot, which can simplify installation.

|

Selecting Styles and Profiles

An important aspect of choosing the most suitable product for a project is understanding the differences and advantages between Concealed-Fastener Systems and Exposed-Fastener Systems. Choosing the right panel style and profile is essential for both functionality and appearance.

- Concealed-Fastener Systems: These panels create a flush, overlapping design available in widths from 8 to 16 inches, enhancing water-tightness and providing a refined appearance.

- Exposed-Fastener Systems: These panels, available in widths of 24 to 36 inches, are generally more economical and quicker to install. Though they may have a less streamlined appearance. They still offer aesthetic flexibility through various color options and shadow lines.

Available profiles include flush, ribbed, standing seam, and corrugated designs.

Available profiles include flush, ribbed, standing seam, and corrugated designs.

|  |

Selecting Finishes and Colors

Finishes and colors not only affect the visual appeal of the building but also its performance.

- Kynar® PVDF: This multi-layer finish is widely used for its high UV protection and is suitable for commercial projects.

- Siliconized Modified Polyester (SMP): Often chosen for residential applications, this two-part paint system provides good durability.

- Polyester: Recommended only for interior liner panels, where UV exposure is minimal.

- Manufacturers typically provide a selection of standard and custom colors, each with varying ratings for Solar Reflectivity, Initial Emissivity, and Solar Reflective Index. Specialty finishes may include options like Crinkle Coat and Cor-Ten AZP.

Choosing Metal Wall Panels

When selecting metal wall panels, consider the following factors:

- Environmental Suitability: Determine the most appropriate metal for the project's location. For example, aluminum is preferred in coastal areas due to its corrosion resistance.

- Thickness Requirements: Assess the intended use and traffic levels in the building. Thicker panels, such as 18 gauge for steel or .050 for aluminum, are recommended for high-traffic areas.

- Design Considerations: Collaborate with your manufacturer’s representative to align the wall system with your design goals.

- Installation Quality: The longevity of metal wall panels is significantly influenced by installation. Ensure that experienced professionals handle the installation.