Masisa® Fingerjoint moulding is a trim made by joining short pieces of wood together using interlocking finger joints. It maximizes wood usage, provides strong and stable connections, and resists warping and shrinking. The pieces are pre-painted with a water-based coating, PVA (Polyvinyl Acetate), and calcium carbonate. They are then painted in one solid color with a semi-gloss top coat, all applied during the manufacturing process. The moulding is available in different profiles, offering a seamless and continuous surface.

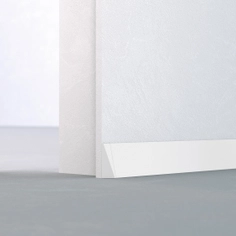

Fingerjoint mouldings find widespread application as baseboards, crown moulding, door and window casings, chair rails, wainscoting, picture rails, panel molding, decorative accents, shelving, cabinetry, and ceiling beams. They add a finished look, architectural detail, and decorative accents to walls, ceilings, doors, and furniture. With their ability to be easily painted and customized, Masisa® MDF moulding provides a solution for enhancing the aesthetic appeal of any space.

Masisa® offers eight designs of Fingerjoint mouldings:

- Raw FJ mouldings

- Jesso Primed FJ mouldings

- Prefinished FJ mouldings

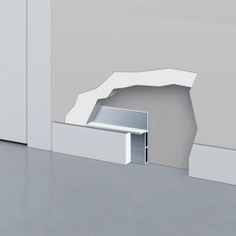

- Split Jambs Raw & Jesso

- Flat Jambs Raw & Jesso

- Frames Raw & primed

- "small" FJ mouldings Jesso and Prefinished

- FJ S4S boards raw, Primed & prefinished

Technical Specifications

| Substrate | Radiata Pine |

| Adhesive | Non-structural synthetic adhesive of exterior grade, based on polymers. |

| Painted | Water-based semi-gloss top coat, applied in the manufacturing process. |

| Pre-Painted | Coating based on water, PVA (Polyvinyl Acetate), and Calcium carbonate. |