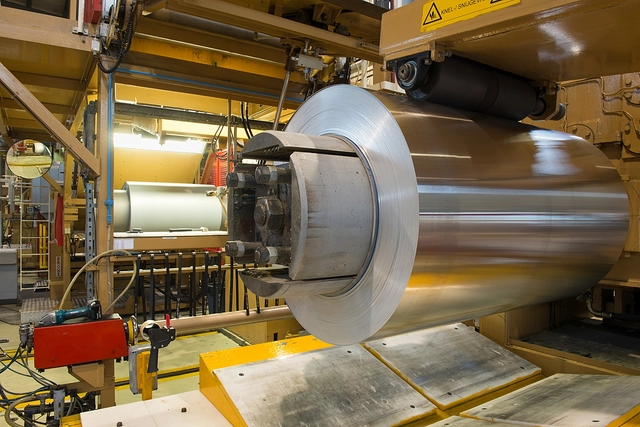

Euramax uses a Coil-coating process to provide custom finishes for metal products. This is a process by which flat aluminum surfaces can be painted. Several coats are included and then the sheet aluminum goes through a cooking process. 25000km of aluminum are painted each year and over 80% of all painted roof and facade panels are produced out of coil-coated metal.

EuramaxLab Support Services

A specification team called EuramaxLab supports architects in specifying coated surfaces with in-depth experience in coating for cladding panel fabrication. The team provides architects with an extensive choice in metal envelope design and works side by side with their customers to understand their business, needs, and challenges.

- Custom coating development

- Custom color development

- Precision color matching

- Metal sampling

- Mockup service

- Network of panel manufacturers

Finishes

- Metal Colors

- Textured Finishes

- Dual-Tone Colors

- Design Patterns

- Solid and Metallics

- High-Performance Coatings

- Standard Colors

- Transparent Coatings

Coil Coating Process

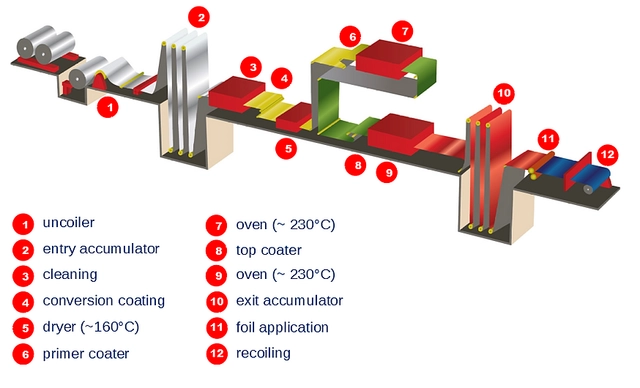

Coil coating or pre-painting is an industrialized process in which large metal coils go through a series of fully automated production steps in a continuous and highly automated process prior to the final fabrication stages.

The process was born in the 1950’s. Since then, the fundamental benefits of painting “in the flat” and subsequently bending and cutting the material into shape have not changed.

Advantages

- Uniform layer and consistent color

- High quality and long lifetime

- Large choice in coating qualities