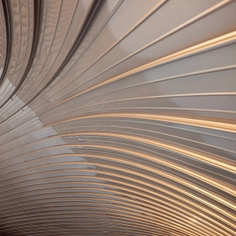

Euramax uses the coil-coating process to provide finishes for metal products that last a lifetime. Multiple coating layers are applied; after every coating layer, there is an oven step. Multiple aluminum alloys are available on which virtually every color can be applied.

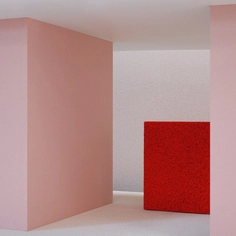

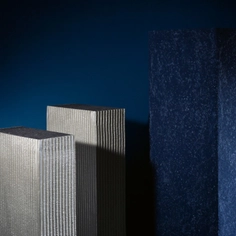

Solid and Metallic Finishes

In addition to offering a white portfolio of colors and glosses, Euramax can custom-develop virtually every solid and metallic color.

Top Coating

The binder is the main building block of coatings. It defines many characteristics of the coating. Euramax supplies a wide range of coating types: PE / HDP / PUR-PA / PVDF and FEVE. Coating type defines:

- Long term performance and warranty period

- Flexibility and abrasion resistance

- Color and gloss level

EuramaxLab Support Services

Euramax has a specification team that supports architects in specifying coated surfaces with in-depth experience in coating for cladding panel fabrication. The team; EuramaxLab helps to provide architects with an extensive choice in metal envelope design and work side by side with their customers to understand their business, needs, and challenges.

- Custom coating development

- Custom color development

- Precision color matching

- Metal sampling

- Mockup service

- Network of panel manufacturers

Finishes

| | | |

| Champagne Metallic | Brilliant Champagne Metallic | Dark Grey Metallic |

| | | |

| Pearl Beige Metallic | Pearl Gold Metallic | Gold Metallic |

| | | |

| Manganese Metallic | Pearl White Soft | Phoenix White |

| | | |

| Cloud Grey | Pure White Gold | Silver |

| | | |

| Oyster Gold | Tawny Orange | Blue Green |

| | | |

| Shark Black | Quartz Zinc Design | Snow White |

| | | |

| White | Silver Metal | Grey Alu |

Important

Not all paint types are suitable for all environments. In areas with high sun intensity, close proximity to salt water, and chemical installations it is important that the right coating quality is chosen. In these cases, contact the architectural support on EuramaxLab.