Euramax uses the coil-coating process to provide finishes for metal products that last a lifetime. Multiple coating layers are applied; after every coating layer, there is an oven step. Multiple aluminum alloys are available on which virtually every color can be applied.

Transparent Coatings

This coating is built from a semi-transparent topcoat in combination with a colorless pre-treatment. The system shows the natural metal aesthetics of the substrate below.

The transparent nature of the coating reveals the substrate's texture, aesthetic variation of the metal, and slight color nuances. Euramax performs intensive checks and controls to guarantee a refined surface finish.

Guidelines

- End-use must be ≥ 1.5 km from coastal areas

- No end-use in heavy industrial/corrosive environments

- Limited end-use between 30° Northern Latitude and 30° Southern Latitude

- Maximum and minimum order quantities apply

- Bare material may vary in color/show small irregularities

EuramaxLab Support Services

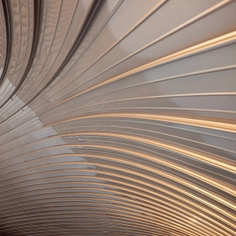

Euramax has a specification team that supports architects in specifying coated surfaces with in-depth experience in coating for cladding panel fabrication. The team; EuramaxLab helps to provide architects with an extensive choice in metal envelope design and work side by side with their customers to understand their business, needs, and challenges.

- Custom coating development

- Custom color development

- Precision color matching

- Metal sampling

- Mockup service

- Network of panel manufacturers

Finishes

Gloss Range: Matte (10 Gloss Units) - High Gloss (90 G.U.)

| | | |

| Line Alu Champagne | Line Zinc Quartz | Line Titanium |

| | | |

| Line Zinc Grey | Line Red Copper | Line Sand Dollar |

| | | |

| Line Light Brown | Line Pale Brown | Line Gold |

| | | |

| Line Golden Tan | Line Anodic | LIne Brushed |

| | | |

| Line Brushed | Line | Clear |