Unique architecture for an impressive timber construction

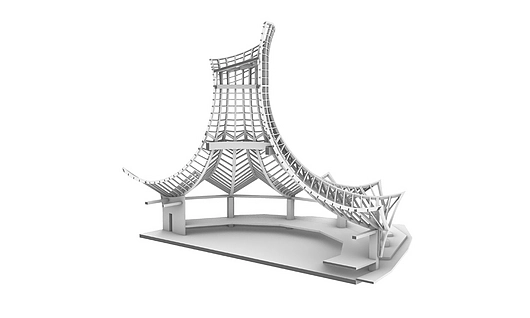

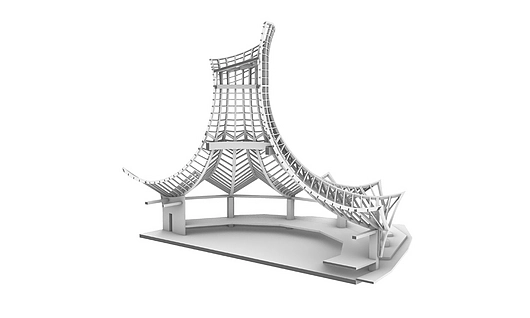

The 26-metre-high tower in a curved timber supporting structure is the eye-catcher of the building and yet another exceptional Free Form of construction. The new building, inspired by architects Carlos Martinez Architekten AG, was described as a bold, innovative design by Rapperswil councillor Thomas Furrer, Head of Construction, Transport and the Environment. The cantilever roof, designed as a prismatic shell structure, is surrounded by irregularly shaped sheet metal sheds. The tower is clad with a metal facade.

In addition to the planning, Blumer Lehmann was also responsible for the 3D modelling.

«We generally like to work with timber. For scheduling reasons, but primarily for environmental reasons.»

Carlos Martinez, Architect | Carlos Martinez Architekten

Multifunctional use of Knie's Magician’s Hat

The sea lions previously kept in the Otarium left the children’s zoo at the end of October 2019. Instead, the magician's hat will host events with a new direction all year round. With a capacity of approximately 500 people, the building is suitable for a variety of uses and is equipped with a retractable stage platform and an extended stand.

«I come into the magician’s hat every day. I love this building. Everyone who enters the building says wow!»

Franco Knie Senior, Co-owner | Gebrüder KNIE, Schweizer National-Circus AG

Production of the elements for the timber-supporting framework

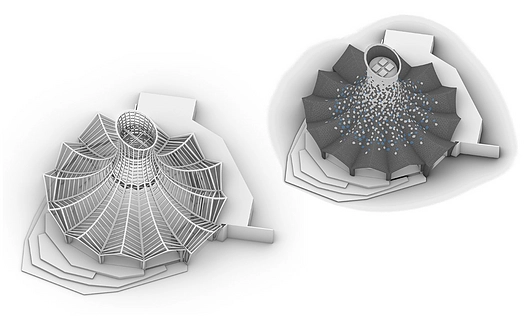

The timber elements for the Knies Zauberhut were produced at the Blumer Lehmann factory and fully assembled straight away. The facade was also fitted directly onto the elements by their project partner, the metalwork specialist Brönnimann. The prefabricated components were then delivered to the construction site and assembled there.

«The biggest challenge was making the whole structure a reality within eight months.»

Stefano Ghisleni, General planning | Ghisleni Partner AG

Assembly on the construction site

The weight and size made the assembly of the large elements of the supporting framework extremely challenging. The large roof elements weigh approximately 4 tonnes and the final component, the hat, weighs almost 20 tonnes. The outer construction was very challenging in terms of the precision required during assembly. However, it was eventually possible to join it all together to form a circle.

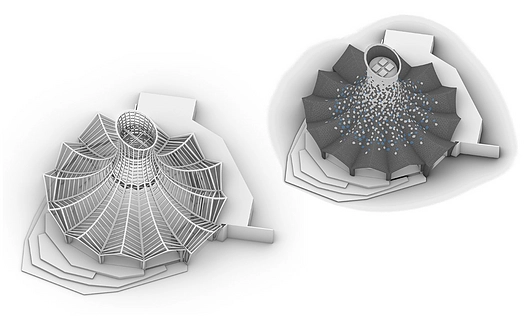

| The timber supporting framework in detail: the shear forces on the ridge and collar beams – where the surface of the roof is folded – are absorbed by single-axis curved laminated timbers and are passed into the concrete supports in the lowest points of the roof valley via recesses at the top end. A concrete tension ring around the support heads holds them together. |

| Two pressure rings – fitted at a height of 11 metres and 18 metres respectively – stabilise the load-bearing diagonal cladding, which is only five centimetres thick. The detailed plan involved the peak of the hat being fully prefabricated when put in place. With a diameter of around seven metres and a weight of 18 tonnes, it was assembled with great precision. |

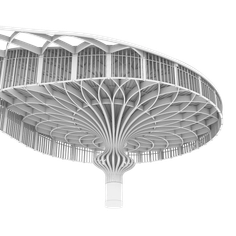

| The pavilion roof has a diameter of 32 metres. During the day, the arena is accessed via the south side. For evening events and deliveries, the northwest gateway is used. On the north side, the roof rests on top of the side rooms, which are situated underground. Terraced elements compensate for the difference in the ground levels. |

If you desire more news about Blumer Lehmann register here for their newsletter.