Hofmann Facades offers total solutions for natural stone facades using traditional and innovative cladding materials, knowledge of building envelope technology and stone manufacturing capabilities.

Natural Stone Facade Cladding

Natural stone requires no energy to transform and very little energy to quarry and fabricate; it can be 100% recycled to aggregate, gravel or brick. Stone has a low level of embodied carbon as well as operational carbon since natural stone-clad buildings require only 30% of the energy to heat and cool compared to glass facades. Natural stone’s durability and ease of maintenance give it an extended lifecycle compared to other cladding materials; as does the graceful aging of stone-clad buildings.

Portuguese Limestone Range:

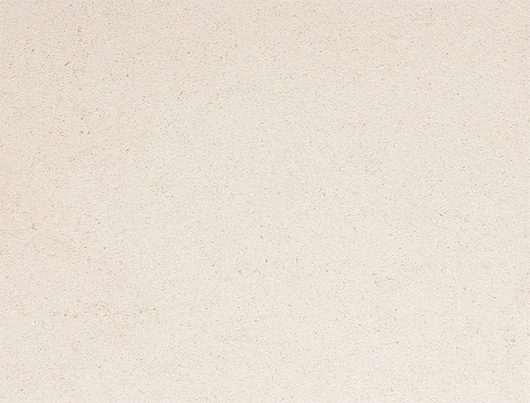

Creme Royal Limestone and Creme Sintra Limestone by Hofmann Facades were formed 150 million years ago. The stones exhibit prehistoric fossils such as ammonites and belemnites, making each individual piece unique.

The stone can be used for any facade application in any climatic condition. This limestone is also suitable for interior and exterior applications making it possible for designers to bring the stone inside and outside with seamless transitions.

| Creme Sintra Limestone | |

| | |

| Creme Sintra Blasted | Creme Sintra Honed C60 |

| | |

| Creme Sintra Honed C120 | Creme Sintra Aquapower |

| Creme Royal Limestone | |

| | |

| Creme Royal Honed | Creme Royal Blasted |

| | |

| Creme Royal Aquapower | |

Worldwide Project References:

- Creme Sintra Limestone

- Maintor Palazzi Frankfurt

- Rocco Forte Charles Hotel Munich

- O2 Arena Berlin

- Brooklyn Point New York

- 50 West 66th Street New York

- Rosewood Hotel McNair Houston Texas

- Creme Royal Limestone

- 20 Ropemaker Street, London

- Opera Tower, Frankfurt

- ML 47, Frankfurt

- Ritz Carlton Hotel, Berlin

- US Embassy, Berlin

- House Liebermann/House Sommer, Berlin

- Kunstinsel Hamburg

- LVMH Store Goetheplaza, Frankfurt

Sustainability Benefits

- Low carbon footprint

Natural stone was created during planetary formation. In contrast to other cladding materials, natural stone does not need to be manufactured at great energetic cost. Only 3% of the manufactured cost is used for energy from block extraction to installation on site. - Long term durability

Natural stone is the most durable material available further reducing its ecological benefit. - Lower lifecycle cost

Rear-ventilated natural stone facades reduce the operating expenses of a building compared to a pure glass facade. Particularly during warm months, a large part of the energy required for cooling can be saved by employing thermally insulated natural stone cladding. - Renaturalization of stone quarries

After decommissioning natural stone quarries are re-naturalized. Within the short term, they turn into natural biotopes attracting a wide array of plants and wildlife. - Renewable practices

Hofmann Facades has been using renewable energy sources in form of solar, hydro, and geothermal for a long time ensuring a significantly reduced energy footprint of all their products. They are also able to recycle their products and waste material 100%; making bricks from stone powder created during the block cutting process. Larger waste is used for aggregate, gravel, and fertilizers.