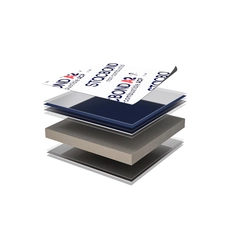

STACBOND® FR panels from STACBOND are composed of two aluminium sheets and an inner fire-retardant core of thermoplastic resins with mineral charge.

The panels have excellent mechanical properties such as great rigidity, excellent flatness and impact resistance.

They comply with the majority of requirements for fire-resistance classification:

- UNE EN 13501-1:2007 – B-s1, d0

- PN-90/8-02867 – NRO

- NFPA 285 – PASS

- ASTM E84 – A CLASS

STACBOND® composite panel

STACBOND® composite panel is composed of two aluminium sheets and an inner core of thermoplastic base and mineral charge. It has excellent mechanical properties, providing bending rigidity with reduced weight, surface flatness, durability and ease of maintenance.

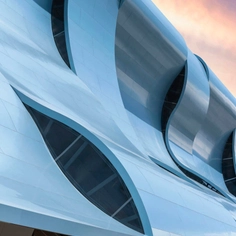

It is specially designed for ventilated facades of new construction as well as for their renovation or rehabilitation. It provides adaptable solutions to all fields of architecture.

Its manufacturing standard consists of an outer sheet of aluminium alloy 5005 and an inner sheet of 3105. There are three different cores available depending on their mineral charge (from 0% to more than 90%), which may be non-combustible or fire retardant, and are classified (in accordance with UNE 13501-1:2007) as A2-s1, d0 and B-s1, d0.

It offers a full range of colours, glosses, textures and natural finishes. It can also be supplied in any colour from the RAL / PANTONE / NCS charts. Please enquire us for details.

STACBOND® composite panel is available in multiple standard dimensions up to 2000 mm wide. Other dimensions can be supplied under request.

Features & Benefits:

- All RAL colours possible

- Excellent weight/surface value

- Easily conformable

- High resistance to UV rays

- rapid and simple assembly

- High impact resistance

- Excellent dimensional stability

- Totally recyclable