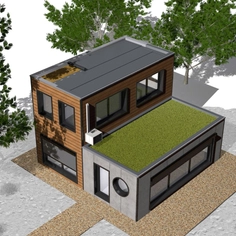

Façade weatherproofing systems from Effisus come in a choice of Breather and AVCL membrane systems, each with properties that make them useful for different situations. Effisus Breather and AVCL membrane systems are usually applied as facade liners and have a severe impact on facade fire propagation, both externally and internally.

The AVCL membrane (known as an Airtight Vapour Control Layer System) is installed on the inner face of the wall and provides a vapor barrier. The Breather system is vapor permeable and installed on the outer layer of the building. When using one of these membranes, use the chart below for proper installation advice, and follow the steps outlined to prevent common faults.

Preventing Common Faults

Faults can happen when the systems aren't installed properly, follow these steps to get the best possible performance:

- Seal perforations

Make sure that the membrane perforations are all fully sealed - Perform compatibility tests

Membranes should be specified noncombustibility or limited combustibility with minimum Class A2-s1, d0 on BS EN13501-1. - Check tapes, adhesives, and sealants

To ensure they are not allowing differential movements - Test tapes, adhesives, and sealant as a complete system

The tapes, adhesives, and sealants used in conjunction with the membranes should be tested and certified as part of the membrane system always replicating the end use. - Perform detailing

Installing the Membrane Systems

| | Breather Membrane System | AVCL Membrane System |

| System Function | Waterproofing vapor permeable system. | Airtight vapor barrier membrane. |

| System Location | It should be installed on top of the external insulation (cold side) protecting the entire facade composition. However and depending on the cladding brackets' complexity (size/shape) it is acceptable that breather membrane systems be fixed on the top of the sheathing board. The weatherproofing design of the breather membrane systems should be done in detail and on a project-by-project basis. | AVCL should be located on the internal face (warm side) of the back wall and fixed on top of the vertical Galvanized Steel SFS Studs. The weatherproofing design of the AVCL membrane systems should be done in detail and a project-by-project basis. |

| Installation - Fixing | Double-sided adhesive/sealant tape spaced minimum @500mm (placed vertically or horizontally). Membrane mechanical fixed shortly (1 metal plate per/m2). | Double-sided adhesive/sealant tape spaced minimum @500mm (placed vertically and horizontally).

Membrane mechanical fix not required. |

| Installation - Perimeter Sealing | Double-sided adhesive/sealant tape (thickness > 1,50mm) applied continuously on top of the weatherproofing EPDM membranes or any other substrate always allowing the interface movement (windows frame/sheathing board; parapet wall/ roofing membrane; concrete/sheathing board, etc.). | Double side adhesive/sealant tape (thickness > 1,50mm) applied continuously on the connections of ACVL membrane edges/end laps to concrete, aluminum or any other substrate allowing always the interface movement (AVCL/Windows frame; ACVL/Concrete Slab, etc.). |

| Details | All the nails/screw perforations < 25mm dia. should be sealed with a patch of 50x50mm of double-sided adhesive tape. The facade perforations with irregular shapes and over 25mm should be studied in detail case by case. All the tapes, adhesives, and sealants should be applied when it is not raining and the temperature is above 50C. Primer is required for temperatures below < 50C; Care should be taken on porous surfaces such as concrete. | All the nails/screw perforations < 25mm dia. should be sealed with a patch of 50x50mm of double-sided adhesive tape. The facade perforations with irregular shapes and above 25mm should be studied in detail case by case. All tapes, adhesives, and sealants should be applied when it is not raining and the temperature is above 50. Primer is required for temperatures below < 50; Care should be taken on porous surfaces such as concrete. |

Membranes for Fire Protection details some of the membrane products available from Effisus.