-

Use

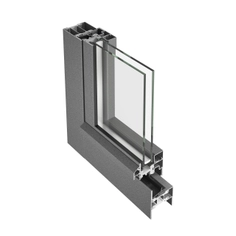

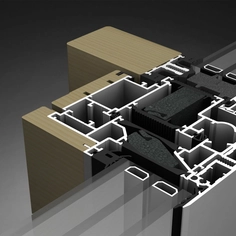

Translucent structural sandwich panel -

Applications

Commercial -

Characteristics

Glare-free, thermal performance, energy-efficient, low maintenance, visual privacy, durable, graffiti and vandal resistant, hurricane, explosion venting and blast rated options

Kalwall® was selected to be the signature feature in the expansion of a historic 1920’s era warehouse that is home to this artisan small-batch distillery designed by Jonathan Barnes Architecture and Design of Columbus. The tiered structure is a 55-foot (17 m) alteration to an existing building that transforms the essential character of the original structure.

Balancing design, cost, and function can be a complicated, lengthy, and expensive process. Sometimes only one element is needed to bring everything together. In the Middle West Spirits expansion project in Columbus, Ohio, Kalwall® translucent sandwich panels was that pivotal element.

In addition to a tasting room, bottle shop, and office, the expansion needed to accommodate new distillery equipment to increase production. Working within a restricted footprint, a center portion of the warehouse’s original steel bow truss and wood roof was removed. Kalwall® panels were used to clad the entire new structure to turn it into a translucent, white monolithic tower. In the daytime, it has a striking and subtle presence and becomes a glowing, beacon at night.

Kalwall® translucent sandwich panels have a secondary use in this case by providing the owners with a bright space that allows them to easily monitor the equipment within the distillery. Kalwall®’s daylight modeling service allowed the architects to design the building so that different elevations transmit different amounts of light to provide completely balanced, museum-quality daylightingTM.

Kalwall® panels fulfilled the required design and function aspects, and they were also particularly appealing for the cost savings. The single-source cladding solution was both within budget and could meet the construction timetables. The decision to use Kalwall® was made after the excavation work had started as a way of reducing the number of steel supports required. This was made possible due to the span capability and the lightweight nature of Kalwall®.

Awards

- AIA Columbus’ 2017 Architecture:

Honor Award

Kalwall® Specification

| Panel | 2.75 ̋ | 70 mm |

| Grid core | plank |

| Exterior FRP | crystal |

| Interior FRP | white |

| System finish | aluminum #79 |

| U-Value | .23 | 1.25 Wm2K |

| Solar Heat Gain Coefficient | 0.28 |

| Visible Light Transmission | 20% |