In supermarkets, renewing a floor can require great technical efforts and a lot of time that affects business. A new solution that avoids these disadvantages and opens up potential has been developed in the form of DryTile floor tiles from AGROB BUCHTAL. In Dornseifers Frischemarkt (food product market) at Much/Germany approximately 2,000 square meters of new ceramic tiles were laid in only four working days in the autumn of 2018 using DryTile from AGROB BUCHTAL.

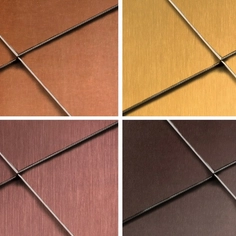

The market was closed for two and a half weeks in order to implement a new tile floor and other building measures within an extremely short period of time so as not to inconvenience customers. The complete renovation included replacing and re-arranging refrigeration units, adapting electric installations, painting, modifying lighting and re-stocking shelves. The main change was the AGROB BUCHTAL DryTiles in the series Valley in a discreet, elegant pebble-grey color.

The 60 x 60 cm format ceramic tiles used an extra thickness of 15 mm because of static and rolling loads caused by shelves and pallet lifting trucks. The four-day turnover represented just a fraction of what would have been required in the case of a conventional re-flooring method.

Installation Sequence

A local company was responsible for the flooring and implemented a sequence of work steps to install the floor in record time:

- On Sunday at 9.00 a.m. the team prepared the base by grinding the previous floor covering down to level it.

- At 4.00 p.m., the laying of the first 550m2 of DryTile tiles started and were finished by 6.30 p.m.

- On Monday morning, from 8.00 to 12.00 a.m., the laying of the next 550m2 followed.

- After that, there was a break because the tiles loaded on one truck were finished and the team needed to await the next shipment.

- On Tuesday from 9.00 a.m., the pointing continued and the remaining tiles were laid.

After that, tiling works were stopped again to wait for the other trades to catch up with the work. - On Friday and Saturday morning, the DryTile works were finished, the work having been done over a total of only four working days.

On top of the speed, attention to detail was carefully considered, exact cuts of the DryTile tiles at adjoining structural elements (pillars, floor outlets, walls) or flush filled and perfectly straight joints prove this.

DryTile Details

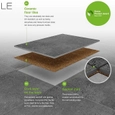

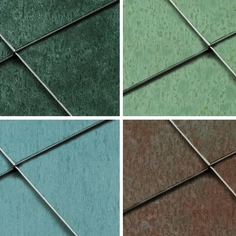

DryTile are high-quality ceramic tiles from AGROB BUCHTAL, they are provided with a thin cork layer on back, applied with a special durable technique at the factory. This cork layer has an exactly defined, slight projection on all sides to form a precise narrow joint when the tiles are laid side by side. Another benefit is the reduction of packaging allowed by the cork layer that protects the tile in transit.

A special pointing compound explicitly developed for the system is used to fill the joints. Before pointing, the covering can be walked on immediately, and after pointing, the surface can be walked on after 12 hours and is fully load-bearing after another 12 hours. The laying is carried out “dry“ without tile adhesive which permits a laying time up to 8 times faster.