When designing the façade of a building the designer must balance practical and technical requirements with the aesthetics that will define the identity of the building. Vertical batten facades are increasingly popular as they are an elegant façade solution that can bring a tactile warmth and shadow-play dynamism to a building. The design and specification of a vertical profile façade is a crucial part of creating a beautiful a functional façade that will endure the ravages of use and the elements.

Selecting your vertical profile

The first step to designing a façade with vertical profiles is to select the material and product of the batten. The primary decision is whether to specify natural wood or an integrated aluminum composite system. The natural warmth of wood is attractive but there are significant variability and design challenges that come with its use. Natural wood is heavy, prone to warping, fading and leeching and requires significant maintenance over its life span. Wood-look aluminum composites however present a viable alternative that combines the aesthetics of wood with the light-weight durability of aluminum.

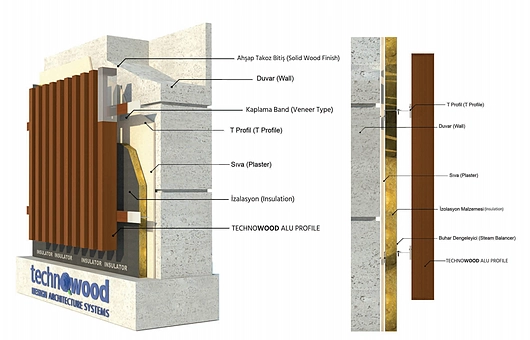

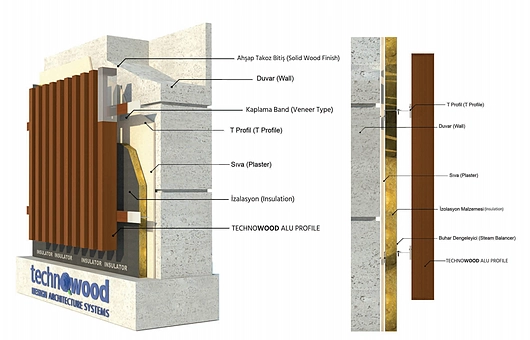

Technowood AluProfile is a façade profile system where the profiles are laminated with natural wood veneers, combining wood aesthetics with metal resistance. This hybrid system produces long-lasting claddings, with the main advantage of extreme climatic resistance while being lighter than natural wood cladding. AluProfile acts as a barrier against flames and is not affected by worms, insects or fungi making it ideal for ventilated façades as well as decorative wall cladding.

The main advantages of Technowood AluProfile are;

- Resistance to organic decay including rot, fungi and insects

- Fire resistance – A2 class fireproof

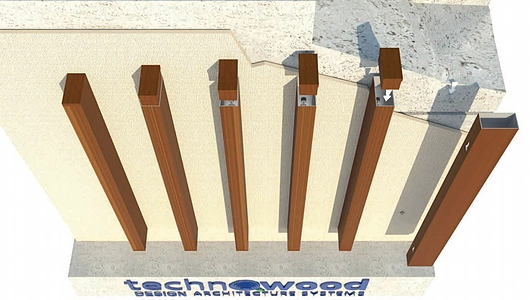

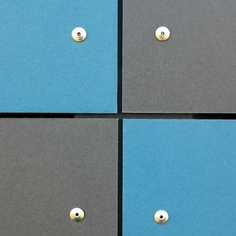

- Easy and fast installation that does not require visible fixings

- Recyclable

- Long lengths with 6m standard length and 7.5m lengths available

- Guaranteed against delamination for 20 years

- Climatic resistance including extreme climates, humid and sea spray

Profile size, finish and spacing

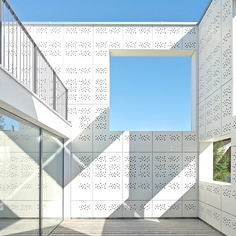

The dimensions, finish and spacing of the vertical profile have a significant impact on the final appearance of the façade. Dynamic facades can be created for larger projects with the specification of large cross-sections with generous spacings. Smaller, more intimate buildings can be enhanced with a delicate façade that can result in a subtle textured look with finer gauge profiles.

Technowood AluProfile is produced with all four sides wood veneered which are available in six wood coatings (afrormosia teak, walnut, American oak, mahogany, ash, and beech) and seven varnish color options. For high volume orders however custom sizes and wood tones can be manufactured. The range of finish options available from Technowood ensures that a designer can specify a product that suits the building style and context.

As a standard, the endpoints of the profiles are open, but they can optionally be produced as closed with solid wood.

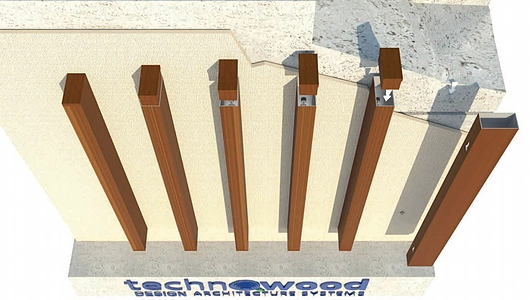

Substrate and fixing methodology

Finally, the designer must ensure that the profile façade has the appropriate substrate and fixings. Technowood AluProfile is designed to be installed over a solid substrate, with or without insulation. The profiles can also be extended beyond the solid substrate base to create sections of open screening. A proprietary T-Profile is used to connect the vertical profiles to the substrate, a combination of rust-proof mechanical fixings and double-sided bonding tape are used to ensure that the whole assembly is securely fastened and resistant to movement and decay. The resulting façade is free of visible fixings and presents a clean uniform appearance.