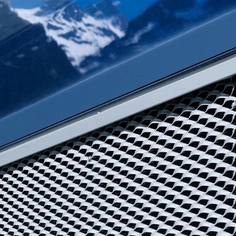

RHEINZINK presents an angled standing seam façade system made from titanium zinc. Angled standing seams are distinguished by particularly low material stresses. Unlike double standing seams, only one side is closed using a machine or by hand.

Application

Angled standing seam systems are used for metal façade/wall cladding and for small surfaces such as fascias and upstands, parapets, etc. They are ideal for visually separating roof and façade surfaces thanks to their height of approx. 25 mm (.98 in.) and a seam width of approx. 12 mm (.47 in.).

Features

- Small and large surfaces can be emphasized or given striking segmentation patterns

- Angled standing seams can be installed vertically, horizontally, and diagonally using a selection of different panel lengths and widths

- Panels can be installed on cross joints or half-staggered cross seams

- Tapered, concave or convex surfaces can be reliably clad with ease

- The system technology on which the angled standing seam system is based allows use in almost all areas

- Variable design thanks to different panel lengths and widths and different installation directions

RHEINZINK products are optimized for application safety, quality, and durability and can be aligned with individual requirements. The system program is rounded off by matching accessories that enable you to assemble the systems smoothly, reliably, cost-effectively and rapidly.

RHEINZINK panels can be fabricated offsite, or onsite using mobile roll formers.

Custom profiles

- Convex:

Minimum radius for convex rounded, standing seam panels is 0.6 m (approx. 2 feet). Starting from a radius of 12 m (approx. 39 feet), panels can be installed without first pre-rounding them. If the radii are smaller, the panels must be edged by hand and stretched using manual forming pliers or a Biegeboy bending machine.

-

Concave rounded panels

The For concave rounded surfaces, the seam edge must be compressed, which is more technically difficult than stretching. The minimum radius for concave rounded, standing seam panels is, therefore, 2.5 m (approx. 8.2 feet). Pre-rounded panels cannot be installed above a radius of 25m (approx. 82 feet).

- Tapered panels

For reasons of production feasibility, the panel width of tapered panels must be at least 100 mm (approx. 4 in.) and max. 730 mm (approx. 28 in.), depending on wind loads.