-

Use

Cladding panels for roofs and facades -

Applications

Public, sports -

Characteristics

Durability, low-porosity, resilience, ductility, fiber-reinforced UHPC, low maintenance -

Sizes

Façade panels: 9 m x 2.5 m, minimum thickness: 11 cm | Roof panels: 8/9 m x 2/2.5 m, thickness: 35/45 mm

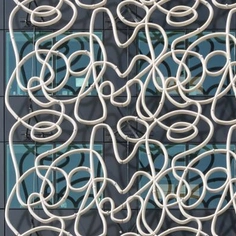

The undulating façade of the Jean Bouin Stadium in Paris, France is clad with a unique Ductal® UHPC envelope that covers 23,000m². Situated in front of the famous Parc des Princes sports facility, the Jean Bouin Stadium was designed by Rudy Ricciotti to be light and airy. Thanks to the superior properties of Ductal®'s Ultra-High Performance Concrete, it was possible to construct a thin, lightweight envelope and waterproof roof from 3,600 self-supporting Ductal® UHPC panels.

The envelope is comprised of three main areas:

- A perforated façade, with self-supporting lattice panels that permit the light to filter through to the interior

- Transition panels between the roof and the façade, with a higher perforation rate and larger curvature

- The roof, made from 1,600 panels with glass inserts

A total of 18 molds were required to produce the 3,600 UHPC panels. For a full year, the precaster (Bonna Sabla) cast thousands of concrete panels at a rapid pace of more than 18 per day.

Testing

Preparation for the assessment involved a painstaking process to create a full-scale prototype underwent a series of laboratory trials and tests:

- Wind fatigue with 78,000 flexion cycles

- Thermal shock

- Soft and hard shock,

- 50 frost and defrosting cycles simulating between 30 and 50 years of the structure's life span

- Continuous water tests to check water tightness

Using 35 mm plate elements helps with directional dispersion of the fibers in the UHPC. The fibers need to flow smoothly into the molds and fully resist developing loads by having a preferential orientation in the matrix. Several panels were tested by cutting small section samples of the UHPC out of each panel in order to prove that the casting process consistently produced correct fiber orientation and therefore viable precast elements for Bonna Sabla.

Roof Panels with Glass Inserts

An architectural requirement for this project was a waterproof roof system. When producing the roof panels, the glass pieces were first positioned into the molds and then the UHPC material was cast around the glass. Waterproofness was guaranteed with a silicon joint placed around the glass before casting. Thanks to Ductal®'s mechanical performances, it was possible to create the thin, triangular panels with 20 to 27% glass. Its high flexural resistance also permitted the design of a slender roof, with an 8 to 9 m overhang.

Exterior Lattice Mesh Façade Panels

Ductal®, allowed the thin lattice panels (some just 11 cm thick) to have more than 50% open space. Blended with metal fibers, the material's superior mechanical performances also allowed the lattice to function as a balustrade.

The use of the same light grey Ductal® UHPC material for the roof and façade panels, cast in a controlled plant environment, resulted in high-quality elements with consistent coloring and guaranteed aesthetic coherence throughout the entire envelope.

Data

| Location | Paris, France |

| Owner | City of Paris |

| Architect & Project Management | Rudy Ricciotti |

| General engineering | Berim |

| Structure and Envelope Engineering | Lamoureux Ricciotti Ingéniérie |

| Precaster | Bonna Sabla |

| Contractor | Léon Grosse |

| Framework engineering | ALTo Group/ Marc Malinowsky |

| Framework | Cabrol |