-

Use

Roofing -

Applications

Transport, public -

Characteristics

Ductile, strong, flexible, ultra-slim, lightweight, resistant, fiber-reinforced UHPC, watertight -

Sizes

Palms Size: 18m length, 2.7m width, 3m depth

The roofing of the Montpellier TGV Station in the south of France is clad in Ductal® panels. For roofing solutions, Ductal® offers precast, fiber-reinforced UHPC panels, reinforced with metallic fibers enabling it to almost match the mechanical properties of steel structures and remove or considerably reduce the need for further reinforcement. All concrete roofing elements (10,000 m² in total) were prefabricated within 4 months and installed with tight geometrical requirements in only 2 weeks.

The southern French city of Montpellier enjoys an average of 2’618 hours of sunshine each year. Now, thanks to the perforated Ductal® roof on the new high-speed (TGV) train station, the sun enters the building to welcome travelers as they benefit from greatly reduced travel times between other major French and Spanish cities. Designed within the Projet Oz: Nature Urbaine (urban nature) project, which aims to fill a 350-hectare urban area with green space as well as housing, offices and transport links, the station design incorporates nature-inspired elements both inside and out; from the platforms to the garden parvis.

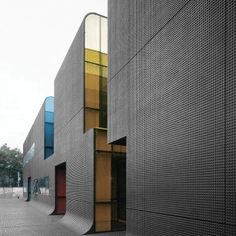

Architect Marc Mimram drew inspiration from the Mediterranean surroundings in the inclusion of a perforated Ductal® UHPC roof, which will filter direct southern light into the station. The roof is made of 115 precast modular Ductal® palms. Each unit is just five centimeters thick, but over 18 meters in span, made possible by the strength and durability of Ductal® UHPC even in very thin panels. They are perforated in a random pattern.

The station's platforms are landscaped to reflect the natural inspiration of the entire project. Major Ductal® execution challenges concerned among others, the control of the fresh UHPC rheology for concreting, controlling the fiber orientation and precision of the tendons location, ensuring absence of cracking during demolding and transportation phases (before post-tensioning), and geometrical control of the final palms installation (+/- 2 mm tolerance for the bearing points).

Data

| Location | Montpellier, South France |

| Delivery | 2017 |

| Contracting client | SNCF Réseau |

| Architect | Marc Mimram |

| Ductal® palm design | Architect: Marc Mimram | Design office: LRing |

| Project size | 10,000m2 roofing elements in White Ductal® Stainless Steel Fiber |

Why Ductal®?

Ductal® layer homogenously ensures durability, protection from sun and rain, and provides natural ventilation of the concourse thanks to the 18m open joints between the palms. Making use of Ductal® UHPC's structural and plastic possibilities, the folds of the thinned roofing surface enable a large span to be created, extending from the entrance parvis to the split levels of the station down to the railway platforms. Ductal® B3 FI is the only white-based mineral material offering the technical properties needed to create a design encompassing more than 50% voided space.