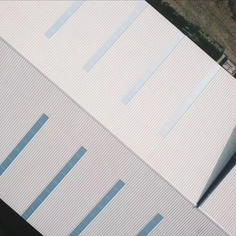

In Oberhausen, a warehouse extension for the Gude GmbH was clad in light-transmissive and colored polycarbonate facade panels from Rodeca. The light building elements were used on the facade of the hall as well as on various housings in the truck loading docks.

Design

The planning group Mesum with architect Wilhelm Bökenkamp designed the extension. The choice of facade material was given special consideration. The warehouse is situated on a main road and therefore needed to stand out without being visually intrusive. The polycarbonate panels were customized with a color scheme. The company chose the two-tone version "Duocolor" with titanium grey on the outside - based on the company logo and "crystal" on the interior to create a bright and friendly atmosphere.

Natural daylight

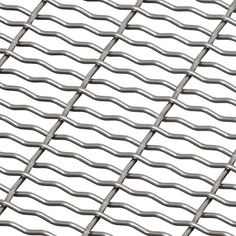

The panels are made of polycarbonate, a high-impact thermoplastic. They are weather and UV-resistant as well as heat-insulating. Thanks to their translucency, they allow some natural daylight through the façade. The chosen material: PC 2550-10 Duocolor, has about 44% daylight transmission. The homogeneous light scattering ensures glare-free natural daylight in the storage areas. From the exterior, the facade appears closed and opaque.

|  |

| Interior | Exterior |

Industrial Material

In contrast to glass, polycarbonate is 200 times more impact resistant. The material does not splinter and thus offers additional safety. Another plus for the industrial sector is that ultraviolet radiation is transmitted less than one percent. Wavelengths up to 380 nanometres are almost completely stopped. This property can play a decisive role in UV-sensitive storage goods.

The Gude GmbH supplies disposable food packaging and hygiene products made of paper, plastic, aluminum, and groundwood, the panels protect the sensitive storage goods against UV radiation.

Heat and Fire Protection

In the new building in Oberhausen, the light building elements form the envelope in front of construction made primarily of steel. Part of the design focus was on the energetic optimization of the building. The panels ensure optimal storage conditions and reduced energy costs both in winter and in summer.

The multi-layered structure means that the facade panels function as thermal insulation. The stronger the panel and the higher the number of layers, the better the U-value will be. The selected PC 2550-10 panels are 50 millimeters thick and have 10 layers and nine air chambers. With this structure, a heat transfer coefficient of U = 0.90 W / m²K is achieved.

In addition to the heat, the fire protection played a significant role. This is especially important when storing flammable materials such as paper or cardboard. PC 2550-10 is a flame retardant building material that meets the additional requirements of "no smoke" and "no flaming droplets".

Construction

The assembly was carried out vertically and the length of the polycarbonate panels was adjusted to the height of the warehouse. It was advantageous that this measure is limited only by transport logistics. System-related frame profiles were attached to the on-site substructure. Due to the multi-layered construction, the panels have a low deadweight of only five kilograms per square meter. In this project, an area of 1,780 square meters was realized within two months with the products from Rodeca.