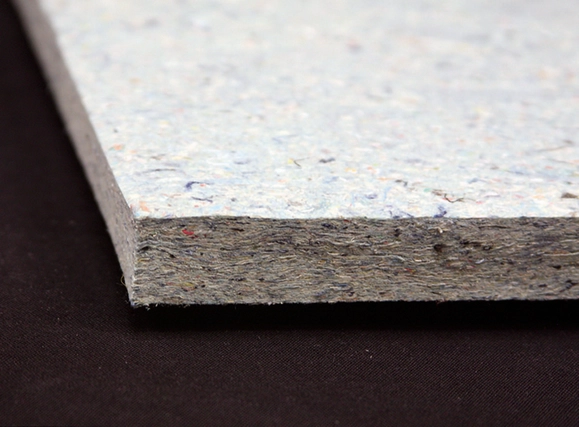

Acoustical Surfaces CFAB™ cellulose acoustic panels are a sustainable alternative to traditional fiberglass and synthetic panels.

Applications

CFAB™ is an inventive, yet sustainable, alternative to traditional fiberglass and synthetic acoustical or thermal panels. CFAB Cellulose Panels are perfect for insulating an area of a project, as acoustic panels/inserts, and a variety of other noise-reduction tasks. Typical applications include:

- Insulation components

- Office panels

- Acoustic panels/inserts

- Molded, flat panel, or lofted parts

Sustainable Qualities

CFAB™ cellulose panels are made from recycled and renewable fibers, consisting of 65-75% recycled content. This makes cellulose insulation a sustainable, alternative to traditional fiberglass and synthetic acoustical and thermal panels. CFAB™ cellulose products are recyclable and don't produce scrap during manufacturing or installation. Through an innovative manufacturing process, the eco cell is produced as a cellulose-based product made primarily from post-consumer and post-industrial paper, with recycled newspaper as the main raw material.

Acoustical Performance

The open design and density of CFAB™ cellulose insulation panels increase sound absorption to control and deaden sound reverberation and echo. CFAB™ cellulose acoustical panels achieve high Noise Reduction Coefficient (NRC) ratings based on the density specified.

CFAB™ Cellulose Panels – Acoustical Testing Data

Absorption Coefficients @ Octave Band Frequencies (Hz)

| Thickness | 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | NRC |

| ½″ | 0.05 | 0.09 | 0.33 | 0.64 | 0.87 | 1.01 | 0.50 |

| 1″ | 0.09 | 0.26 | 0.84 | 1.05 | 1.05 | 1.05 | 0.80 |

| 1½″ | 0.14 | 0.40 | 0.93 | 1.09 | 1.03 | 1.03 | 0.85 |

| 2″ | 0.39 | 0.63 | 1.18 | 1.11 | 1.06 | 1.09 | 1.00 |

CFAB™ Cellulose Panels – Physical Property Data

| Property | Test Method | Value |

| Surface Burning Characteristics | ASTM E-84, UL 723 | Flame Spread: 15

Smoke Developed: <450 (Class A) |

| Critical Radiant Flux | ASTM E-970 | >0.12 w/cm² |

| Corrosiveness | ASTM C-739 | Acceptable |

| Fungal Growth | ASTM C-1338 | Acceptable |

| Thermal Resistance | ASTM C-518 | 3.6 – 3.7 R per Inch |

| Moisture Absorption | ASTM C-739 | Acceptable |

| Odor Emission | ASTM C-1304 | Acceptable |

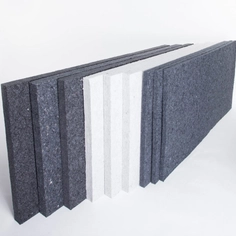

Densities

- 3lb pcf – 1″ Thickness & 2″ Thickness

- 6lb pcf – 1″ Thickness

- 8lb pcf – ½″ Thickness & 1″ Thickness