-

Use

Exterior façades -

Applications

Residential -

Characteristics

Recyclable, lightweight, no visible fixings, easy assembly, non-combustible, low-maintenance, sustainable -

Certification

EC declaration of conformity, A2 class fire rating, FSC -

Guarantee

20-year warranty

46 villas with marble and Technowood wood façades have been built in Bodrum. The aim of the project was to create a complex where families can easily live all year round, with all their needs seamlessly met; where adults and children can spend time individually or together. To this end, a careful study was made into the allocation of social areas.

Apartment sizes vary from 165 to 470 square meters. The terrain in the Gökçebel region has a sloping structure, facing the bay. The project includes social facilities such as a beach club, restaurant, outdoor pool, sports area, indoor parking lot, and sales units.

Project Data

| Location | Yalıkavak, Bodrum, Muğla |

| Architects | AS Architects, Gökhan Aksoy Architects |

| Assistant Architects | Kerime Vural, Özge Karakaş |

| Client | M2 Construction |

| Project Manager | Nuri İnandım |

| Dates | 2015 - 2016 |

| Construction Area | 30.000 m² |

Terrain

The advantage of the sloping terrain means that the ground floor of each apartment is positioned at the roof level of the last, thus the residents can enjoy gardens and terraces privately with uninterrupted panoramic views of the sea. The warm climate meant that car parking is provided underground in sheltered tunnels which serves to also make the project pedestrian-friendly.

Natural Surroundings

The project’s main aim was to create a residential project that integrates itself respectfully into its surroundings. Instead of using white, earth and wood tones were preferred, and attention has been given to expressing nature; the façade, therefore, is natural wood-plated panels, mounted on marble and aluminum panels. The texture of the marble and the heat of the wood give character to the façade design.

Material Choice

Solid wood has become fashionable in construction however it is subject to aging from time and environmental factors causing deformations. Technowood products are made by applying wood veneers to durable materials; this approach prevents unpredictable bending and deformation. Using veneers reduces the consumption of wood by 98% and increases its life expectancy by more than 5 times.

Technowood can be used where traditional wood products can but also where specific details and measurements make the use of other wood products difficult. They are easy to assemble and be produced to specification.

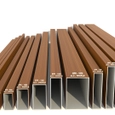

Durable Profiles

The profiles can be aluminum or GRP (Glass Reinforced Plastic), these materials are lightweight, high strength and easy to machine. Their weather resistance durability is utilized with the finish of natural wood from the wood veneers added to the profiles.

Environmental Credentials

In the construction industry, wood is often harvested from trees which take almost 100 years to mature, sustainable forestry is now widely practiced however does not take into account the unpredictability of wood consumption levels 100 years from now. This is why Technowood has paired sustainable forestry practices in line with FSC guidelines with their revolutionary method of applying natural wood veneers to durable materials; thus also addressing the issue of high consumption.