-

Use

Building Envelope (Exterior Glazing & Cladding), Façade System (Pre-fabricated / Unitized) -

Applications

Corporate, Residential, Institutional, Educational, Hospitality, Healthcare and Cultural -

Characteristics

Shop-welded CFMF studs, exterior-grade sheathing, integral punched windows, fully-gasketed aluminum panel-to-panel joinery, AVB membrane coverage, complete with outboard-insulated rainscreen finishes

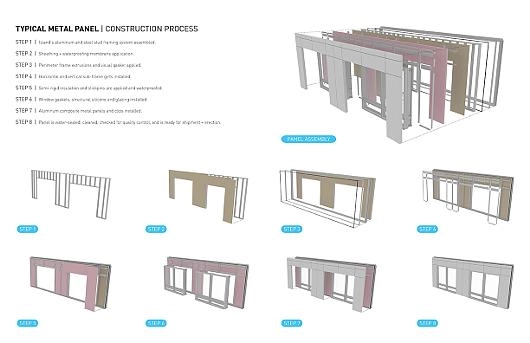

Island’s mega-panel façade integrates light-gauge stud framing with punched glazing and a multitude of finish options, to create a highly-versatile unitized enclosure. Each panel begins as a full-welded steel frame and is wrapped with a proprietary extruded profile, allowing large-format panels to be installed completely weathertight, without the need for scaffolding and caulking.

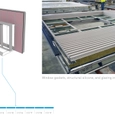

Project-specific insulation, thermally-broken girts, and rainscreen cladding (folded/formed plate, composite metal, terracotta, stone, thin-brick, among others) are applied in Island's climate-controlled factory setting, with QA/QC checks built into each process. After being shipped to the site, the mega-panels are installed by crane, enclosing as much as 400sf of façade per unit. Island’s pre-fabricated mega-panels leverage existing performance testing, thermal data, and extensive mockup fabrication & testing – to create bespoke façade systems that are truly unique.

Diagram of a typical mega panel assembly.

Megapanel facade on Highline 23 by Neil M Denari Architects.