-

Use

Façades -

Applications

High rises, storefronts, offices, apartments, shopping centers or public buildings -

Characteristics

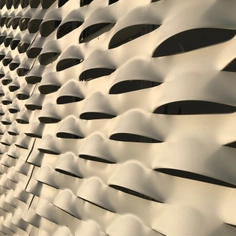

Fire-resistant: A1 and A2s1d0, tailor-made, low maintenance (low porosity), weight: 2.5 t/m3. Ductal®’s self-consolidating behavior and fine-grained texture results in a surface finish that replicates mold materials with the greatest precision -

Certification

Fire classification A1-A2s1d0 (European legislation)

Ductal® Perforated Panels are made with authentic Ductal® UHPC, meaning that every dimension can be achieved, from small to large ones, on-demand. Every texture and color can be imagined. Perforated Panels can be used with well-known fastening systems, and have the best response in fire resistance and durability among all mineral facade materials.

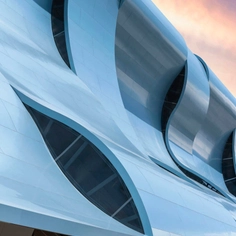

Whether you’re working on high rises, storefronts, offices, apartments, shopping centers or public buildings, you will find that UHPC Ductal® perforated panels solution provides the perfect second skin to protect your building from sunlight while offering an aesthetic, mineral and highly personally designed façade. Highly moldable, Ductal® allows the production of customized, precast lattices to suit any building's specific location and resist sun intensity. The brise soleil solutions offer architects a new range of alternatives for lightweight, durable facades with slim, streamlined shapes.

Whereas the lightweight Ductal® solution reduces glare and noise, it is more durable compared to metal alternatives. The large & thin building envelopes are a real option halfway between tailor-made precast façades and standardized panels.

Main Advantages:

- Fire resistant: A1 and A2s1d0.

- Tailor-made.

- Easy Maintenance (low porosity)

- Ductal®’s self-consolidating behavior and fine-grained texture result in a surface finish that replicates mold materials with the greatest precision.

Technical Specifications:

| Weight: | 2.5 t/m3 |

| Fire classification: | A1-A2s1d0 (European legislation) |

Applications:

Shum Yip Upperhills Loft in China

The Shum Yip UpperHills Loft is a high-end commercial complex with 6 high-rise towers containing offices, hotels and business apartments. The owner of the project needed a solution with high quality and durability, especially considering the impact of climate as a coastal city, as the façade panel requires double skin finishing. Ductal® Perforated Panels have very good fluidity, which allows it to be cast in a closed mold, and achieve high-level surface finishing quality. The façade is designed as a grill, with a 50% perforate ratio, with a 20 mm thickness of the panel frame.

Nike Retail Store in Miami

Located in Miami Beach, the two-story, 31,000+ square-foot "retail experience" is impressive. It's south and west facades are wrapped by a unique brise-soleil made with 180 Ductal® Perforated Panels, designed to incorporate classic Nike patterns. The result is an intricate casting that allows light to filter through to the interior while providing shade outside, creating a distinctive synergy with the surrounding promenade. The selection of materials was an important part of the design process; concrete is one of the most common building materials used in sub-tropical commercial projects.