Envel™ rainscreen cladding panel solutions made with Ductal® provide sustainability, durability, low porosity, fire resistance, and unprecedented aesthetic design flexibility. Envel™ panels can be produced in a vast range of standard or custom colors, textures, sizes and shapes - and achieve complex forms that other materials cannot.

There are two basic panel types:

- Aspect Series panels, available in standard sizes of 6, 8 or 12 -inch widths x 6 feet long

- Format Series panels, available in a range of larger format sizes

Envel™ panels are easy to install and fit securely; they may be installed over traditional wall construction such as concrete, block, stud walls, and continuous insulation systems.

Two basic installation systems are available:

- Hidden Fastening – using an undercut anchor, fasteners are hidden and install with a fast, adhesive-free process

- Face Fastening – installed with screws or rivets and fasteners are left exposed. All panels are pre-drilled for ease of anchor, screw or rivet installation.

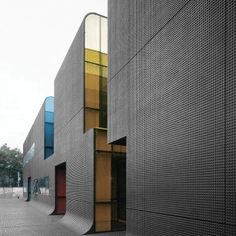

Envel™ panel systems are produced with Ductal® ultra-high performance concrete (UHPC), providing strength, durability, ductility, and aesthetic design flexibility. This combination of superior properties provides unparalleled creative potential and freedom to design thin, complex shapes, curvatures, and highly customized textures.

Ductal® is highly moldable and replicates form materials with amazing precision. Significantly stronger than conventional concrete, it offers better resistance to abrasion, chemicals, freeze-thaw, carbonation and chloride ion penetration. The material’s superior durability characteristics are due to low porosity from a combination of fine and small raw materials selected for their optimized size distribution and chemical characteristics.

Advantages:

Panel Dimensions:

Common sizes:

- 4 ft x 4 ft

- 4 ft x 8 ft

- 5 ft x 12 ft

* Panels can be cut to achieve any size up to 12+ ft

Available Colors:

Technical Details:

| Fire classification: | ASTM E84, ASTM E136 can be performed per project |

| Seismic Performance: | ASTM 501.6 Passed |

| Surface treatments: | Anti-graffiti, Matte, High Gloss, Low Gloss |

| Fixing systems: | Concealed attachments: rail-mounted |

| Face-fastened: | Attachments using screws |

| Corner treatments: | Beveled Corner, Cross corner, One-piece Corner Installation |

Applications:

Lewis Farms Fire Station

This Fire Station project, located in Edmonton, had the challenge of frequently being exposed to harsh, freezing temperatures during the winter and hot temperatures during the summer. Almost all building facades in this area require high-performance properties in order to meet the post-disaster requirements of the Alberta Building Code.

Ductal®'s density and extremely low porosity properties attribute to the material's low permeability characteristics. Water molecules cannot penetrate its matrix, resulting in very high compressive strengths and a superior durable cladding solution that is able to resist impact better than most façade materials. The Lewis Farms Fire Station had an art component that allowed the custom design of the facade's textured panels.

Rosecrance Ware Center

Ductal® Cladding Panel solution offers an innovative and polished terracotta finish in the transformation of a vacant grocery store, near Chicago, into a modern behavioral health services facility. For the facade, Saavedra Gehlausen Architects approved Ductal® cladding as an economical and aesthetic solution. The external cladding, covering a total area of 280 m2, is comprised of approximately 200 precast Ductal® panels, each approximately 60 cm x 213 cm and just 1.27-cm thick - with an attractive terracotta finish.