This vertical cladding for facades is a high-density laminated panel, composed of a core of paper fibers -compressed at high temperature and pressure- and an outer coating highly resistant to weathering and UV radiation. The wood used in the panels has been treated with Everlook®, a component that - without the need for maintenance - extends the useful life of the panel and the stability of its color regardless of weather conditions.

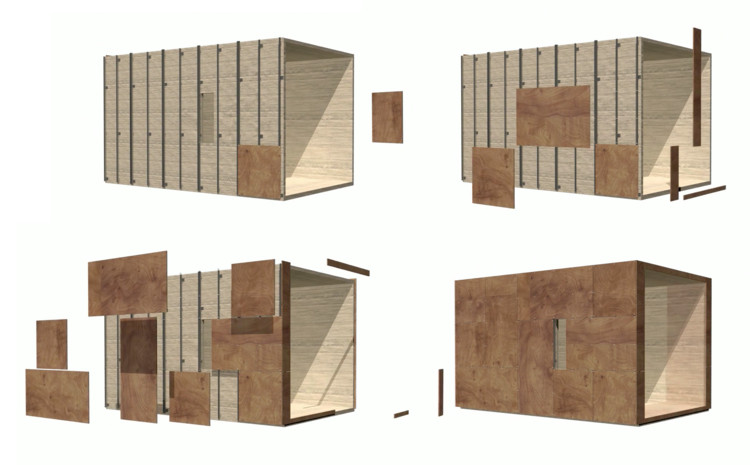

To generate a ventilated facade with these panels, each unit must be installed on vertical profiles, producing an uninterrupted airflow behind the panel. Here's how to do it.

To ensure its correct operation, the panels must be separated from the wall by profiles, installed vertically and forming a ventilated chamber of ≥ 20 mm. To allow air circulation in the chamber, the air inlet and outlet must be located correctly.

Benefits of Ventilated Facade

Permeability / By moving, the air allows the 'breathing' of the façade through the diffusion of water vapor, from the inside out. This makes it possible to avoid condensation forming behind the panels.

Water Protection / The moving air prevents the infiltration of rainwater into the structure of the building.

Thermal insulation / The thermal bridges between the outer structure and the load-bearing structure are eliminated, saving energy by reducing temperature fluctuations in the interior.

Solar protection / The 'breathing' of the facade helps to avoid the overheating of the interiors by direct radiation during the summer, helping to reduce the thermal energy that enters the interior of the building.

Acoustic Protection / The absorption of noise occurs as it is a system composed of several layers.

Installation

Substructure

The substructure of vertical profiles is fundamental within the process since it facilitates the circulation of air behind the panels when separating them from the building. This hidden structure must be designed to meet all static requirements and support the average wind load of the place where it is being installed. The inclination of the façade, the dimensions and the thickness of the wooden panels, and the chosen mounting system should also be considered.

The minimum support width of the profile for intermediate points is 60 mm, and 80 mm for the points where two panels meet.

Wood Substructure / If the project is in a dry area, without frequent rains, you can build a substructure with wooden slats, which must be treated beforehand. It is recommended to add PVC joints or closed cell polyethylene foam on the exposed surfaces, to extend the useful life of the structure.

Metal substructure / For wet or rainy areas, it is recommended to build a substructure of metal profiles; galvanized steel or aluminum. In areas near the sea, stainless steel profiles should be used.

Installation Systems

1. Exposed screw or rivet fixing

This mounting system includes visible mechanical fasteners, which may be screws or rivets lacquered in a similar tone to the color of the panel.

2. Fixing with plugs

This system includes covers of 14.25 mm in diameter with the same finish of the panels, hiding the fixation with screws.

3. Hidden fixing with bracket hanging system

In this system, the fixing support is a hidden mechanical element.

4. Hidden fixing with overlapping slats

This system consists of overlapping flaps, available in two different widths: 190 and 290 mm, both with a maximum length of 2440 mm.

Window details

Corner details

Aplication of Ventilated Façade

Residencia en Varese / Franzetti Primi Architetti Associati - Varese, Italia

Residencias Teega en Puteri Harbour / Liu & Wo Architects - Johor Bahru, Malasia

Museo y Bodega del Cognac Alliance 1892 / TOTEMENT | PAPER - Chernyakhovsk, Kaliningrado, Rusia

Residencia Golden View / Workshop AD - Anchorage, AK, Estados Unidos

Find more detailed information here.