Lightweight aluminum curtain wall facades are offered by Metawall®, the

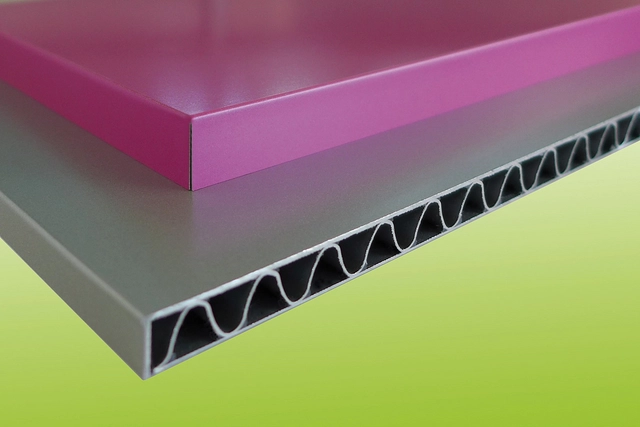

product variation of Metawell® that specializes in facade cladding. The aluminum facades have a simple design made from lightweight, rigid aluminum sandwich panels created for curtain wall facades. Rear-ventilated facades can also be realized with Metawall® aluminum sandwich panels.

The aluminum sandwich panels are created using a continuous production process that enables the fabrication of unusually large facade elements with flat surfaces. Less substructure is required since the panels remain dimensionally stable over a larger span. Protecting the core against corrosion gives a high corrosion resistance for the overall panels which are 100 % recyclable without previous material separation.

Colors

Different colors including RAL, NCS, BS, Pantone, and metallic colors are offered as well as the chance for individual color schemes. Unlike other sandwich panels, Metawell® panels can be powder-coated on request – so individual coloring for smaller quantities is also possible.

Advantages

- Aluminum sandwich panels with corrugated core for large facade elements

- Weight savings due to lightweight construction

- Economical, due to larger spans and less substructure for big facade elements

- Various colors available (custom designs, decors, gloss, metallic colors, and colors according to RAL, NCS, BS, and Pantone)

- Sustainable, thanks to raw material savings and full recyclability (without previous material separation)

- Excellent corrosion protection (also of the core)

- BIM-objects for ArchiCAD and Revit

Products

Depending on the requirements of static and fire classification, there are two different aluminum facade products:

| | Rear-ventilated facades with Metawall® A2 | Curtain wall facades with Metawall® B1 |

| Description | With properties similar to Metawall® B1 the aluminum sandwich panel Metawall® A2 offers a panel thickness of 15 mm a fire classification of A2. | With the low weight of 5.2 kg/m2 Metawall® B1 is extremely stable and the 10mm panel thickness convinces in terms of energy efficiency and sustainability by saving raw material. |

| Overall thickness | 15 mm | 10 mm |

| Weight | 6.8 kg/m2 | 5.2 kg/m2 |

| Non-visible fixing method | riveting | Gluing (up to 4300 mm) and riveting |

| Perfect flatness for big elements | max. 1460 x 6000 mm | max. 1470 x 6000 mm |

| Fire classification acc. to EN 13501-1 | A2 – s1, d0 (non combustible), NFPA 285 and ASTM E84 (passed) | B – s2, d0 (flame retardant) |