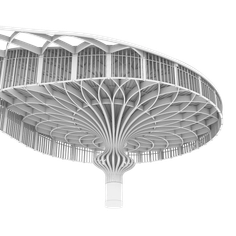

Flagship Free Form wood projects such as the Cambridge Mosque demonstrate the dramatic range of shapes modern wood construction can take. Over an area of 2340 m2, the timber construction accommodates a prayer room for 1,000 worshippers, a café, and two apartments. The calm, focused atmosphere in the building’s interior is generated by 30 Free Form, interconnected tree-like timber pillars. The geometry is guided by a historic Islamic pattern called 'Breath of the Compassionate'. The pattern evokes the rhythm of breathing and thus life.

The parametric design was done by Marks Barfield Architects in collaboration with geometric artist Keith Critchlow and the timber construction was overseen by Blumer-Lehmann, experts in timber construction. As this structure is a mix of various prefabrication types, including Free Form components, traditional ribbed and timber-framed construction and cross-laminated timber elements, the various different production facilities at Blumer-Lehmann AG were involved.

Design Challenges

The demanding Free Form construction of Cambridge Mosque offered up some tricky problems for the programming and production teams at Blumer-Lehmann. Such as the forms of the 30 trees. They seem the same at first glance, yet some of the wooden beams connect with concrete, some with wood and others connect to nothing at all. They are also double-curved and cannot be placed on a flat surface for processing.

Parametric Planning

By developing a type of modular system with 2,746 individual components in 145 varieties, the challenging tasks of production, logistics, and installation were solved. To do this, the project team took advantage of the benefits of parametric planning. Parameters are used to define elements, nodes, and connections. The outcome of this planning meant that the design resulted in only 23 blanks proving it to be very economical.

Parametric planning of the Cambridge Mosque made it possible to organize the elements into different types based on shape, size, and connection. The parametric data efficiently and precisely controlled the production machinery directly and produced each component in the required design and quantity. The most economically viable means of production. The effort of parametrization pays off, particularly for large, complex Free Form constructions.

Facts & Figures

- 3,000 free-form components

- 2,000 m2 exterior walls

- 1,200 m2 interior walls

- 2,000 m2 roof area

- 2,000 m2 cross-laminated timber

- 63 Skylights

- 3 staircases

| Project type | Free Form |

| Client | Cambridge Mosque Trust, Cambridge |

| Architect | Marks Barfield Architects, London |

| Location | United Kingdom |

| Year | 2017 |

If you desire more news about Blumer Lehmann register here for their newsletter.