.jpg?1624956731)

The automation of architectural design and rendering has been further accelerated by digital production tools. Tools such as 3D printers, assembly robots, and laser cutters, have all but perfected the design and construction process and have proven essential in optimizing resources, improving precision, and increasing control of the process.

In woodworking, the most frequently used digital production tools are milling machines or CNC (computer numerical control) routers. These tools facilitate the rendering of 2D vectoral drawings and 3D models, codifying them into instructions for the machine to follow and execute. Through this process, which starts with digital archives (typically created using design software widely known as AutoCad), milling machines and CNC routers can rapidly and precisely cut wood, producing ready to assemble pieces.

.jpg?1624953648)

- Related Article:

50 Downloadable Digital Joints For Woodworking

Some of the many advantages of automating the wood cutting and molding process is optimizing work time and efficiency while decreasing materials waste and labor costs. This has also led to an increase in the open sourcing of design codes, ready for use in CNC machines. These open source designs allow users to download files that have been created and perfected by various online collaborators. The user can then customize these designs to fit the needs of their own project and then upload it directly to a CNC machine, either in a FabLab or a woodworking shop, which will then process and cut the wood according to the file's instructions. This allows people in any part of the world to design and build in a way that is as simple as printing a PDF file. Open source design codes ready made for digital fabrication with CNCs allow, among other things, designers to connect with local suppliers and clients, cutting out middle men and transportation costs.

.jpg?1624953649)

- Related Article:

BIM and Digital Design: A Closer Look at How Mass Timber Goes from Factory to Building Site

The sheer variety of shapes that can be cut and created by a CNC machine coupled with the processes that generate more durable materials, such as nail laminated timber, cross-laminated timber, and glue-laminated timber, is enough to demonstrate wood's unlimited capabilities as an architectural resource. To highlight just some of the many applications for digital woodworking, we've compiled 10 projects from throughout Latin America that demonstrate the various capabilities of digital carpentry in creating everything from furniture, to surfaces, to full structures.

Structure

Woven House / Santiago Pradilla + Zuloark

- Location: Cundinamarca, Colombia

- Year: 2019

“The way in which Casa Tejida is designed and built, inspired from digital manufacturing and open source systems, makes it understandable by all. The project has a premise to explore prefabricated solutions , also with a high degree of craftsmanship, where wood and metal guilds have produced the pieces of a puzzle to be assembled very quickly on site.”

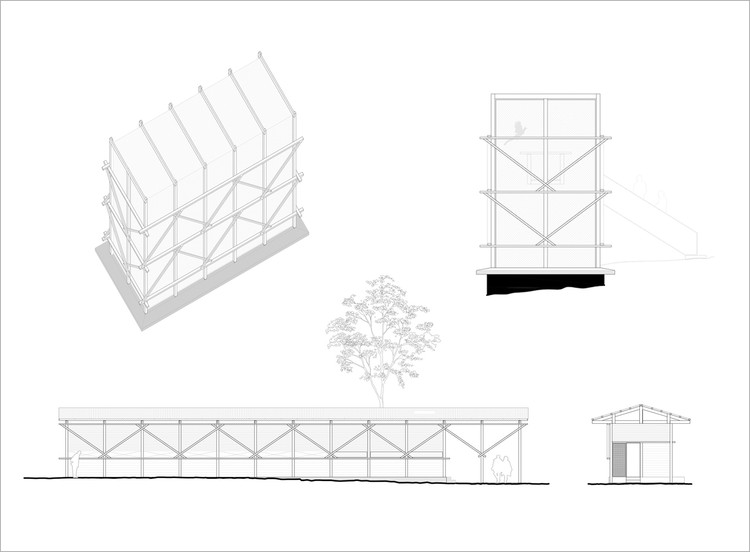

Aviary and Stable Park El Encanto / DRAA

- Location: Osorno, Chile

- Year: 2019

“The wood digital cut system is a prefab technology and given the distance to urban centers and scarce qualified workmanship was chosen. The whole timber mounting process was done by a team of two people directed by a supervisor engineer in 10, without leaving any remaining materials, waste or major damage to the land or animals.”

Cantino Rural Primary School / Taller Viga Maestra

- Location: Vilcun, Chile

- Year: 2020

“We used wood as the primary material not only because it evokes a sense of rurality and simplicity but it also blends with the scenery within which its placed. The structure was laid out using Cadwork software and build using CNC technology to form the wooden pieces provided by Timber."

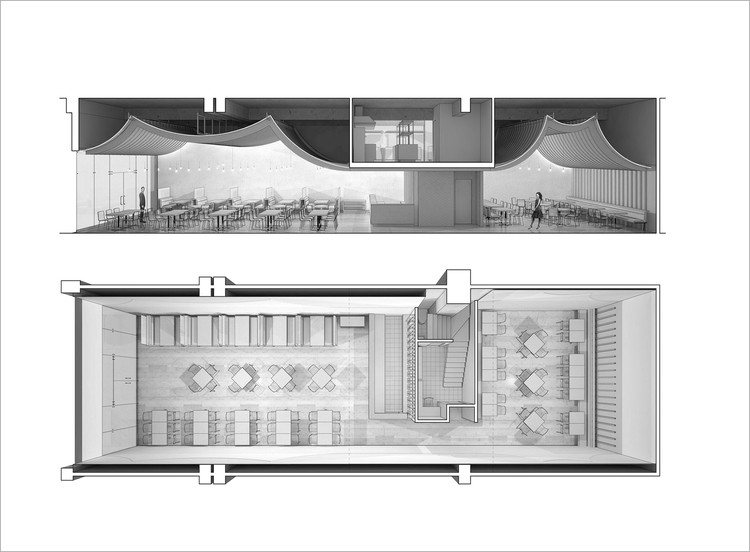

Curacautín Market / Taller Viga Maestra

- Location: Curacautin, Chile

- Year: 2021

“The structure is principally built with radiata pine and laminated wood. The structure was modeled with Cadwork software and executed using CNC technology, which made for a quick and clean assembly and decreased the project's overall carbon footprint."

- Related Article:

How to Design and Build a Wooden Structure with Hidden Joints

Furniture / Objects

Mountain Nazca / mar arquitectos + xamploo

- Location: Mexico City, Mexico

- Year: 2017

“The materials, fabrication methods, and construction methods were driven by the project's designated production time. Digital fabrication allowed the project team to control every aspect of the process and produce the necessary amount of pieces for assembly, cutting down on construction time and allowing the team to focus on the design details of the project. The details of each assembly piece were already planned out, making the project entirely pre-fabricated."

- Location: Bairro Itaim Bibi, Brazil

- Year: 2017

“The carpentry for Youse was inspired by fab labs, embodying the raw materiality of the CNC navy plywood sheets. The landscape design visually warms up the whole space and improves the quality of the work environment. The squads are rooms designed to group multidisciplinary teams for special projects. Located along the floor and taking up to 12 people, these spaces are semi-open systems that bring privacy to the teams while they are accessible to lounge areas.”

Restaurante DECK / RAMA estudio

- Location: Quito, Ecuador

- Year: 2018

“The primary goal of the design was the optimal use of materials in order to cut down on waste, construction time, and transportation and assembly costs. Through digital fabrication, more than 65 wooden panels were cut using a CNC – Router, making for 85% to 95% accuracy of each panel and reducing the use of materials as well as the overall cost of the project.”

- Related Article:

Open Source Furniture: Download, Print And Build Online

Finishing / Interiors

Glocal Design Station / ROW Studio

- Location: Mexico City, Mexico

- Year: 2011

“Since the MDF panels can’t be bent to generate curves we decided to use them as a sequence of plans that would generate the virtual form of a complex curved surface as the wireframe negative of the volume contained in a orthogonal box made by the module of the panels cut with a CNC router. When the plans intersect in the three directions of space they form a grid of shelves that serve as display and storage space for the magazines and other products.”

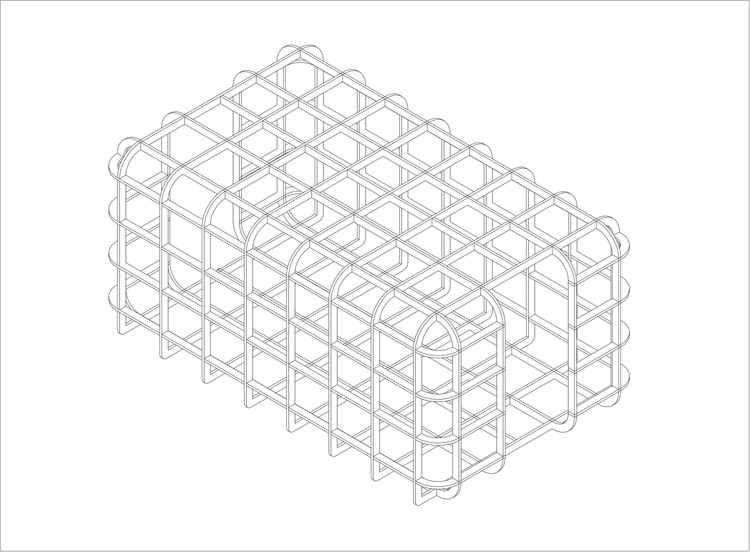

Happy Panda Restaurant / Hou de Sousa

- Location: Quito, Ecuador

- Year: 2013

“The ceiling is composed of CNC cut plywood and heavyweight interfacing (a fabric used to stiffen dresses and suits).The project schedule was swift, and necessitated expedient methods of construction. While resources and materials for small scale construction is somewhat limited in Ecuador, the dramatic boom of the advertising and signage industries there has lead to a proliferation of CNC machines, laser cutters, and large scale printers. A key priority when designing the project was to make use of these technologies, so as to minimize the need for skilled labor and reduce construction time and cost.”

Tienda Garimpê / numa arquitetos

- Location: São Francisco do Sul, Brazil

- Year: 2016

“Industrial plywood is the principal material used in the project. From the doorknob to the lighting, each furnishing was pre-fabricated using a CNC milling machine and then assembled in situ using unskilled labor and few tools. In all, the entire assembly process took only 5 days.”

- Check out more articles on Digital Fabrication as well as our top articles on wood.

This article is part of the ArchDaily Topic: Automation in Architecture. Every month we explore a topic in-depth through articles, interviews, news, and projects. Learn more about our monthly topics. As always, at ArchDaily we welcome the contributions of our readers; if you want to submit an article or project, contact us.

.jpg?1624956731)

.jpg?1624953649)

.jpg?1624953648)